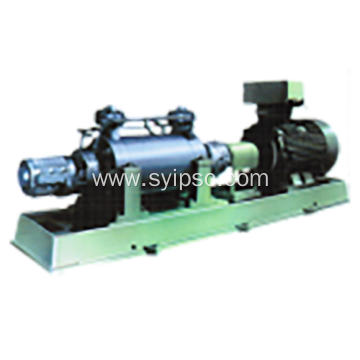

TD Hydrogenation Feed Pump for delivery of solid particles of petroleum products, petrochemical and other process chemical industry products. Temperature of the medium being transported 0-210 ℃.

Performance range:

Flow rate (Q): 30-750m3/ h

Yang Cheng (H): 600-2850m

Spit pressure (P) :6-28MPa

Pump structure:

TD-type pumps are horizontal double-shell, inner shell of segmental Multi-Stage Centrifugal Pump can not move the case out of the pipeline within the housing for maintenance. Suction pipe, threw up the tubes are arranged vertically, horizontal center line of support. Mainly from the pump cylinder pump, pump cover, inhalation, middle, guide vane, shaft, impeller, cooling chamber body, balance disc, balance sets and other parts. Pump rotor mounted on the shaft of the impeller, balance disc and other parts. Heat the impeller onto the shaft sequence, both ends of the pump oil from the lubrication of the four wedge structures composed of radial bearings and thrust bearings, thrust bearings for the two-way forced circulation lubrication grease, respectively, with temperature protection and monitoring instrumentation. Axial force from the balancing device to balance the remaining axial force in the special conditions and additional axial force generated by the thrust bearing to bear.

Labeled mechanical shaft seal, the friction heat generated by the payment of forced circulation liquid away. Circulating fluid through a dedicated cooler and filters to ensure the circulating fluid clean.

Transmission:

Low speed, the pump diaphragm coupling through the original motivation for direct drive. High speed, the pump through the membrane coupling and growth through the gear box growth, then the original motivation driven by membrane coupling. Look at the pump from the drive direction is clockwise.

2 impeller, balancing drums, bushings, etc. in turn mounted on the shaft, rotor components made by the both ends of the bearing radial and axial spacing.

3 by the double-balanced drum axial force balance, the residual axial force from the thrust bearing to withstand.

4 with the wear bar to inhale, middle, spit connected into one segment.

5 bearings sliding bearings, thrust bearings angular contact ball bearings or thrust bearings Mitchell.

6 using self-lubricating bearing lubrication (oil ring) or forced lubrication.

7 static metal sealing surface sealing, wound pad seals and "O" ring seal.

8 dynamic seal for mechanical seal, wash rinse cycle way from, outside tap and rinse washing three ways.